|

|

150 SCFM Heatless Desiccant Air Dryers HLS Series by Van Air Systems - HLS-150

|

|

MSRP: $7,700.00

Price: $6,160.00

You Save: $1,540.00 (20 %)

Model Number: HLS-150

Manufacturer: Van Air Systems

* Whole number only

|

- A : 86

- B : 25

- C : 20

- D : 6

- E : 85

- F : 8

- In/Out Conn.(FLG) : 1NPT

- Desiccant Weight per Tower : 83

HLS Series Small Flow Heatless Desiccant Dryers.

HLS Series Small Flow Heatless Desiccant Dryers.

55 through 150 SCFM

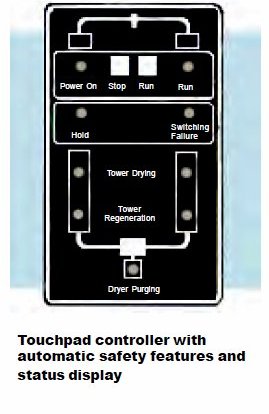

Touchpad Controller

-40F or -100F Pressure Dew Point

No Purge Air Loss When Compressor Unloads

Built In Cycle Monitor

Extremely dry compressed air for your lower flow applications

Models HLS-55 through HLS-150 deliver a low -40F dew point to protect pneumatic equipment and processes from the harmful and costly effects of compressed air moisture.

For even greater protection, these models offer the flexibility of switching to a -100F dew point when needed.

Models HLS-55 through HLS-150 are ideal for :

- Instruments

- Critical Point-of-use Applications

- Laboratory Use

- Paint Spraying

- Dust Collectors

The hold feature preserves system pressure, conserves purge air and saves energy by automatically closing the purge exhaust valve when the compressor unloads or is on standby. It resumes the cycle when compressor flow returns.

The cycle monitor with LED and remote contact allows immediate notification of any disruption of the operation cycle.

The controller also features a membrane panel housed in a NEMA 4X enclosure which clearly displays dryer operation with LED indicators for each step in the cycle sequence.

Benefits of the HLS Series

- Dependable

- Low Maintenance

- Easy to monitor

Standard Equipment

Standard Equipment

- Status indicator LEDs (see front)

- Activated alumina desiccant

- Control air filter

- Enamel exterior finish with primer on towers, piping and supports

- NEMA 4X control enclosure

- 115V/1PH/50-60HZ supply power

- Cycle monitor (FTS) LED and contact

- Touchpad controller

- Dryer Hold feature

- -40F dew point, adjustable for -100F dew point

- Permanently lubricated inlet transfer valve

- Purge exhaust muffler

- Removable stainless steel desiccant diffusers

- Tower pressure gauges

- Welded steel vessels (models 120 and 150 are to ASME code)

Optional Equipment

- 230V/1PH/50-60HZ supply power

- Mounted filters

- Mounted filters with three-valve bypass

- Digital dew point meter with alarm contact and recorder output (shipped separately)

Regenerative dryers must have clean, oil-free inlet air

Lubricated compressors: Dryer must be equipped with the proper prefilters as shown in the chart. An afterfilter should be installed downstream of the dryer to prevent desiccant particle migration.

Non-lubricated compressors: A particulate or coalescing prefilter is recommended to prevent pipe scale and dust from fouling the dryer. An afterfilter should be installed downstream of the dryer to prevent desiccant particle migration. |

Product Reviews

|

| | |

|

| |

| | |

|

|

|